The AHR Expo is the world’s largest HVACR event, attracting the most comprehensive gathering of industry professionals from around the globe each year. The Show provides a unique forum where manufacturers of all sizes and specialties, whether a major industry brand or innovative start-up, can come together to share ideas and showcase the future of HVACR technology under one roof. Since 1930, the AHR Expo has remained the industry’s best place for OEMs, engineers, contractors, facility operators, architects, educators and other industry professionals to explore the latest trends and applications and to cultivate mutually beneficial business relationships. The event is co-sponsored by ASHRAE and AHRI, endorsed by many industry leading organizations, and is held concurrently with ASHRAE’s Winter Conference.

Orange County Convention Center

9800 International Drive

Orlando, FL 32819

Mestek Machinery is the industry-leading designer and manufacturer of the most complete, productive, and innovative metal forming solutions for the fabrication of HVAC sheet metal ductwork and fittings. With a half dozen brands and an expanded network of dealers around North America, Mestek Machinery’s extensive network supports HVAC and sheet metal forming and fabricating equipment needs. Mestek Machinery has a combined knowledge and experience spanning over 70+ years addressing every facet of the HVAC duct industry, and developing cutting-edge, precision technologies, and automated manufacturing equipment saving time, money, and labor. Mestek Machinery’s expansive family of brands includes Lockformer, Engel, Iowa Precision, Lion, Roto-Die, and ISM Machinery.

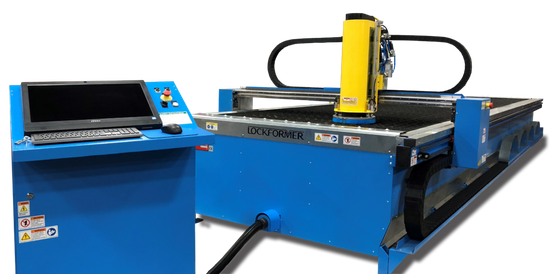

The next evolution in the Vulcan® cutting systems is the Laser-Max 1.5. Featuring a premier fiber laser cutting system, the Laser-Max 1.5 creates a clean, quality cut with minimal heat affected zone on the cut edge. Burr-covered edges common with plasma cutting equipment are eliminated, extending the service life of roll-forming and bending machinery. Big or small, simple or intricate, all jobs are possible with the Laser-Max.

The CORNERMATIC® Combo is an innovative machine that not only inserts and crimps corners into both ends of ductwork, but closes longitudinal Pittsburgh seams on the same ductwork when required. This unique design allows the operator to accomplish both corner insertion and seam closing on one machine without having to handle ductwork between processes.

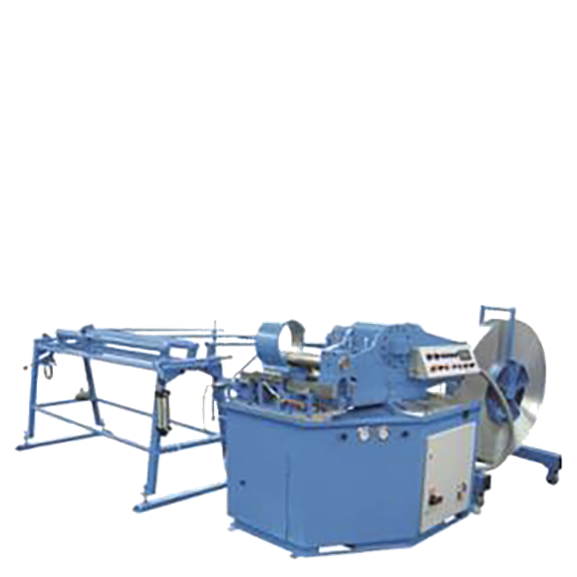

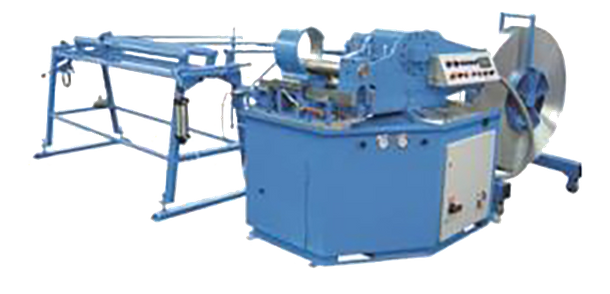

The D-Max Series machines are all revolutionary automatic spiral tubeformers that combine the most advanced technology with one of the smallest footprints in the industry. Unlike other compact models, the D-Max 1.2E/1.6E /2.0E models will not sacrifice speed, power, technology, or quality.

The next evolution in the Vulcan® cutting systems is the Laser-Max 1.5. Featuring a premier fiber laser cutting system, the Laser-Max 1.5 creates a clean, quality cut with minimal heat affected zone on the cut edge. Burr-covered edges common with plasma cutting equipment are eliminated, extending the service life of roll-forming and bending machinery. Big or small, simple or intricate, all jobs are possible with the Laser-Max.

The CORNERMATIC® Combo is an innovative machine that not only inserts and crimps corners into both ends of ductwork, but closes longitudinal Pittsburgh seams on the same ductwork when required. This unique design allows the operator to accomplish both corner insertion and seam closing on one machine without having to handle ductwork between processes.

The D-Max Series machines are all revolutionary automatic spiral tubeformers that combine the most advanced technology with one of the smallest footprints in the industry. Unlike other compact models, the D-Max 1.2E/1.6E /2.0E models will not sacrifice speed, power, technology, or quality.

The quality of your cutting table can determine the quality of your products. The Vulcan® 1600 Waterjet is designed with traditional Lockformer® quality and reliability to eliminate the duct line bottleneck in your shop, while reducing the labor associated with this process. HVAC contractors rely on Vulcan’s® insulation cutting software and table to increase shop productivity, reduce waste, and improve the bottom line.

The Pro-Ductomatic® Front-End Coil Line System provides the fastest feed rate in the industry and the most economical footprint in the world. Every Pro-Ductomatic® Front-End Coil Line System has been designed to maximize return on investment by delivering years of reliable production. This system was designed for light to heavy duty commercial applications and allows future additional components to make this system a complete automated duct line.

The quality of your cutting table can determine the quality of your products. The Vulcan® 1600 Waterjet is designed with traditional Lockformer® quality and reliability to eliminate the duct line bottleneck in your shop, while reducing the labor associated with this process. HVAC contractors rely on Vulcan’s® insulation cutting software and table to increase shop productivity, reduce waste, and improve the bottom line.

The Pro-Ductomatic® Front-End Coil Line System provides the fastest feed rate in the industry and the most economical footprint in the world. Every Pro-Ductomatic® Front-End Coil Line System has been designed to maximize return on investment by delivering years of reliable production. This system was designed for light to heavy duty commercial applications and allows future additional components to make this system a complete automated duct line.